En Trans Sabater, no solo reciclamos, transformamos residuos en recursos de alta calidad. Nuestros procesos innovadores garantizan productos excepcionales a partir de plásticos, madera, cartón, metales y combustibles alternativos. La calidad es nuestra insignia, y la sostenibilidad es la esencia de cada producto que ofrecemos al mercado.

Plásticos

En el corazón de nuestra iniciativa de reciclaje de plásticos, abordamos con precisión diversas variantes, como el Polietileno de Alta y Baja Densidad, Polipropileno, PET, mixtos y otros compounds técnicos. Contamos con un laboratorio técnico altamente especializado que nos permite producir plásticos a medida, asegurando soluciones personalizadas y sostenibles para las necesidades específicas de nuestros clientes.

Entre los últimos desarrollos de I+D+i de Trans Sabater, en colaboración con Tetra Pak, se encuentra el desarrollo de un innovador proceso de reciclado de residuos procedentes de envases de cartón usados post-consumo para bebidas (“UBC”) en Iberia. Trans Sabater ha conseguido, mediante su proceso patentado, reciclar el 100% de los residuos y transformarlos en un nuevo material: Astral.

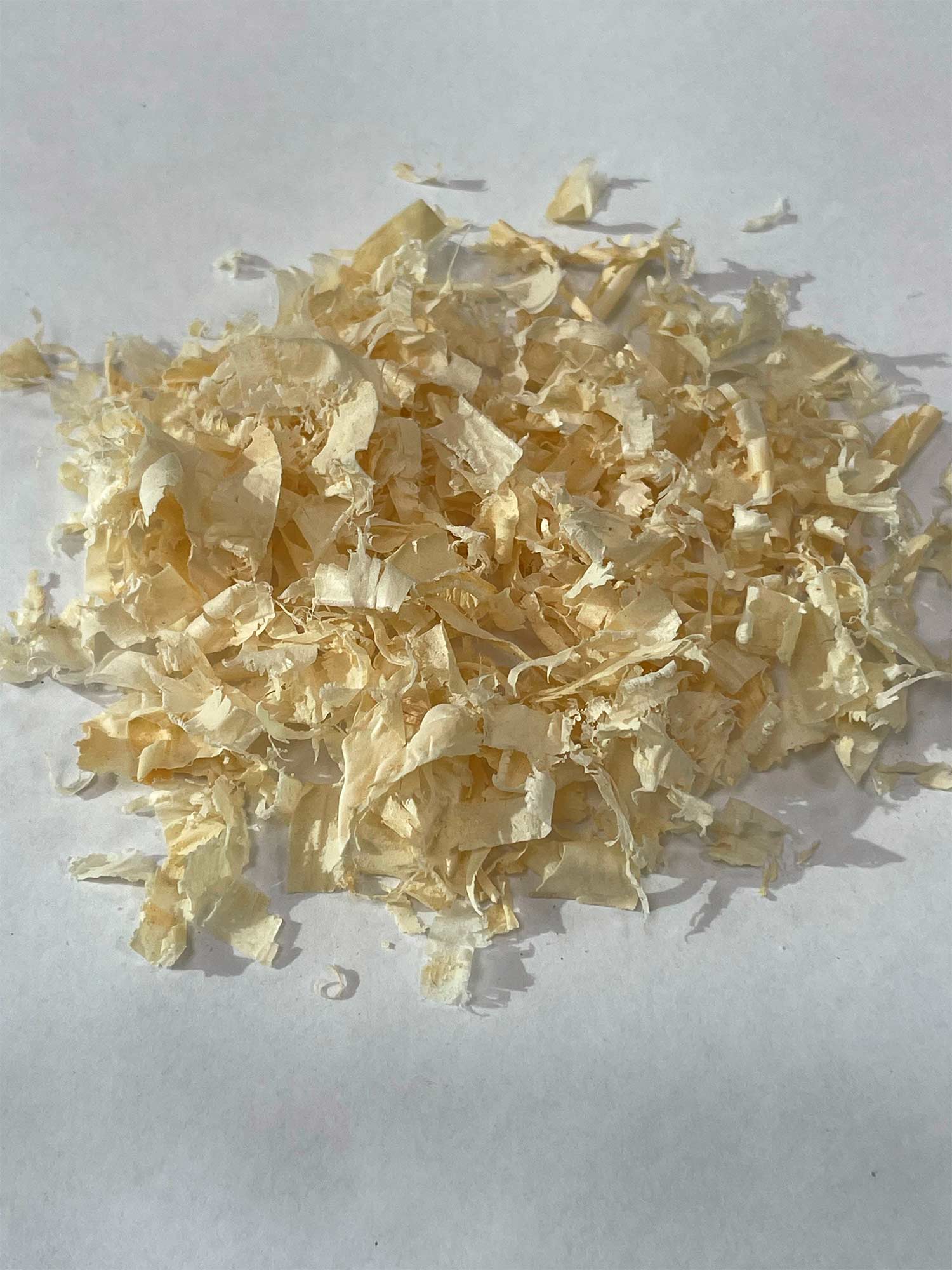

Madera

A partir de la recolección de madera postindustrial y de ecoparques certificados, transformamos este recurso en astilla y serrín de alta calidad. Con la flexibilidad de adaptar el tamaño de la astilla según la granulometría requerida por el cliente, ofrecemos soluciones personalizadas que cumplen con los más altos estándares de sostenibilidad y rendimiento

Cartón

De la recolección de cartón postindustrial a la clasificación y prensado especializado, nuestro proceso garantiza balas de cartón de alta calidad. Con un meticuloso control de calidad, aseguramos un alto porcentaje de contenido de cartón en cada bala, ofreciendo a nuestros clientes un producto final que cumple con los estándares más exigentes en sostenibilidad y rendimiento.

Combustibles alternativos

En la vanguardia de la sostenibilidad, somos pioneros en la producción de Combustibles Derivados de Residuos, transformando residuos y biomasa en energía alternativa. Nuestros innovadores combustibles son utilizados como fuente calorífica en diversas industrias con grandes hornos, marcando la pauta en la filosofía Waste to Energy. En Trans Sabater, convertimos desechos en soluciones energéticas renovables.

Metales

Desde la recogida del metal postindustrial hasta la clasificación especializada, nuestro proceso asegura la obtención de balas de aluminio de alta calidad. Mediante un eficiente sistema de clasificación mediante ópticos, logramos un alto porcentaje de contenido de aluminio en cada bala. En Trans Sabater, transformamos el metal reciclado en soluciones sostenibles, garantizando productos finales de excelencia en cada paso del camino.

Fichas técnicas

Recibirás la(s) ficha(s) en el email que nos proporciones en el formulario. ¡Muchas gracias!